Are you worried about the lack of fuel?

Plants Modular Biodiesel for self-consumption.

Look for the self-sufficiency.

That the fuel is not a concern.

Change the diesel fuel with Biodiesel.

Biodiesel X- B100 es el biocombustible adecuado. El biodisel que se obtiene de estas plantas:

- Reaches the high standards of quality.

- Is friendly with the mechanics of the engines.

- Improves the performance of the engine.

- Prolongs its useful life.

- Reduces the formation of deposits.

- Provides 63% more lubrication.

Plantas Multiplex en venta

Tamaños adaptados a cada negocio

These machines produce biodiesel in a wide range of volume (from 500 lts. until 240.000 liters/day), thus covering the needs of consumption, of fleets of transport, agricultural machinery, transportation, marine, vials, etc

Plant Biodiesel Multiplex 500L

Capacidad de producción 500L cada 2 horas (1 ciclo Batch)

Platform-carbon steel 2 x 4 mtrs.

- 5 HP Motor

- 1 reactor tank intercooler, stainless steel

- 3 Centrifugal Pumps

- Ultrasound equipment

- Filter processes with pressure gauge

- Controls of level and temperature

- Electronic board automatic

Plant Biodiesel Multiplex 2.000 L

Production capacity 2000L every 2 hours (1 cycle Batch)

Platform of carbon steel.

- 10 HP engine

- 2 tanks reactors intercooler, stainless steel

- Centrifugal Pumps

- Ultrasound equipment

- Filter processes with pressure gauge

- Controls of level and temperature

- Electronic board automatic

The best time to produce biodiesel is NOW.

These teams work with ADDITIVES, ORGANIC enzyme-based oils

Used as a raw material crude oil degumming soy or other vegetable oils new, used, or of animal origin.

- Do not require water

- Do not produce effluents or toxic gases

- Do not use boiler.

- Making no noise.

- Have a low power consumption.

We not only sell machines

With the purchase of any of the plants you provide:

- Organic additives

- Kit lab for quality control

- Recipes to use your glycerol

Machines for preparing Biodiesel

A sustainable alternative

Produce your own fuel will provide you with significant benefits:

Economic savings

Reduces costs associated with the purchase of fuel.

Energy self-sufficiency

Less dependent on external sources of fuel.

Flexibility and control

Produced in the quantity and time you need.

Use of resources

Reduci waste by giving it a use.

Environmental sustainability

Contribui to the reduction of emissions of greenhouse gases.

¡Produce your own fuel is an investment that provides multiple advantages!

Do you know what you can use glycerol for?

With our refineries instead of wasting win!

By each production of biodiesel you get a remainder of glycerol that you can use to create more of 60 by-products useful for your field.

Take advantage of your plant multiplex at 100%, and maximize the use of your resources

Not only you will be able to produce biodiesel, but also Agricultural oil and Adjuvant Methylated Organosiliconado with the same machine!!

The Agricultural Oil it is a product that is used in agriculture for various applications. It is used as an agent of crop protection, helping to control and prevent pests, such as insects and mites. In addition, it can be used for the lubrication of agricultural machinery and as an additive to improve the adhesion of plant protection products.

On the other hand, the Adjuvant Methylated Organosiliconado it is an additive that is used to improve the effectiveness of plant protection products, including herbicides, insecticides, and fungicides. It acts as an enhancer, optimizing the penetration and absorption of the products in the plants, which increases their effectiveness in the control of pests.

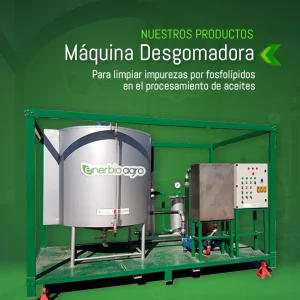

Complement your biodiesel plant with other machines

Learn more of our products designed to help you grow your business.

What is Biodiesel?

Biodiesel fuel is a renewable and biodegradable, produced from vegetable oils, animal fats, or waste oil from the kitchen.

It is a cleaner alternative and sustainable diesel, fossil, as it produces fewer emissions of greenhouse gases and air pollutants, and helps to reduce the dependency on fossil fuels.

Advantages of its use

- Clean combustion: Not containing components hazardous to health and the environment.

- Reduces more than 70% of the emission of toxic gases

- It is biodegradable

How many liters of oil are needed to produce 1 liter of biodiesel?

The typical relationship for the production of biodiesel is about 1:1. This means that, in general, it takes about 1 liter of oil (or grease) to produce 1 litre of biodiesel. However, it is important to note that this relationship may vary slightly depending on the type of oil used and the specific process of production of biodiesel employee.

How long can it be stored?

Biodiesel B100 can be stored up to three years without losing their efficiency.

How do you know if the biodiesel is quality?

The quality of biodiesel obtained may depend on several factors, among them:

Raw materials: The quality and the composition of the oil or fat is used as a raw material for the production of biodiesel can influence the final quality. High-quality oils, such as vegetable oil virgin, tend to produce biodiesel of better quality in comparison with oils or low-quality.

Production process: our plants using the method of cavitation ultrasonic provides response times, greater efficiency and better quality of biodiesel produced.

Storage and handling: The biodiesel must be properly stored to maintain their quality over time. Exposure to sunlight, excessive heat and moisture can degrade the quality of the biodiesel, so it is important to follow the recommendations of adequate storage.

With the purchase of each production plant is provided a kit of laboratory that allows you to perform analysis to ensure the best quality of the biofuel obtained.

Where can I use biodiesel?

Biodiesel has applications in various sectors, from transport to agriculture and industry:

Transport: can be used in diesel vehicles, such as cars, trucks, buses and other means of transport which use conventional diesel. It can also be used in boats and railways.

Generation of energy: biodiesel can be used in power generators and heating systems, as a cleaner alternative and sustainable to the conventional diesel.

Industry: biodiesel is used as a raw material in the production of chemical products, such as lubricants, detergents and other industrial products.

Agriculture: The biodiesel can be used in agricultural machinery, such as tractors and harvesters, as an alternative to more sustainable and friendly to the environment.

Aviation: Although still in an experimental phase, the biodiesel is also being studied as an alternative to the kerosene used in aviation.

What engines can use biodiesel?

In general, modern diesel engines are designed to operate with blends of biodiesel and conventional diesel, although it is important to follow the recommendations of the vehicle manufacturer or by the computer to determine the maximum proportion of biodiesel that can be used safely.

It is important to note that some diesel engines or older engines high pressure may require modifications or adjustments to function with biodiesel, and it is important to consult a specialist before using biodiesel in these types of engines. In addition, it is also important to ensure that the biodiesel that is used to comply with the standards and technical specifications to ensure safe and effective use.

What is better biodiesel or diesel fuel?

The choice between biodiesel and conventional diesel depends on several factors and considerations, including environmental, economic and performance. Here we provide some key considerations:

Environmental sustainability: The biodiesel is considered more sustainable than the conventional diesel, because it is produced from renewable sources such as vegetable oils, animal fats or used cooking oil. To be renewable, contributes to reducing emissions of greenhouse gases and reduces dependence on fossil fuels.

Reduction of emissions: The biodiesel tends to have a smaller carbon footprint in comparison with the conventional diesel, which means it produces less emissions of greenhouse gases. However, the precise reduction of emissions can vary depending on the type of feedstock and the production process used.

Motor support: biodiesel is compatible with most of the diesel engines exist and can be used in mixture with conventional diesel in different proportions. However, it is important to follow the recommendations of the vehicle manufacturer in terms of the blend of biodiesel to ensure optimal performance and to prevent possible compatibility issues.

Performance and efficiency: In terms of performance and energy efficiency, the conventional diesel tends to have an advantage over the biodiesel. Biodiesel has an energy density slightly lower, which may result in a slightly higher consumption in comparison with the conventional diesel.

Availability and cost: The conventional diesel has a wide availability and an established infrastructure for your distribution. Biodiesel, though it is increasingly available, you can have an availability limited in certain regions. In addition, the cost of biodiesel can vary depending on the raw materials used and the factors of production, which can affect their economic competitiveness in comparison with the conventional diesel.

In summary, the choice between biodiesel and conventional diesel will depend on your priorities and specific circumstances. If you value the environmental sustainability and want to reduce the emissions of greenhouse gases, biodiesel can be a favorable option. However, considering the compatibility with your vehicle, the performance and the availability of local, as well as the associated costs to make an informed decision.

Methods or processes of biodiesel production

Among the most common are:

Transesterification basic: it Is the method most commonly used and consists in mixing oil or fat with an alcohol (usually methanol) in the presence of a catalytic base (such as sodium hydroxide or potassium). This process produces biodiesel (methyl esters or ethyl) and glycerin as a byproduct.

Transesterification acid: In this method, we use an acid as a catalyst (such as sulfuric acid or hydrochloric acid) to carry out the transesterification reaction. However, this process is less common due to the need of an additional stage to neutralize the acids present in the biodiesel output.

Transesterification, enzyme: This method uses enzymes as catalysts for the transesterification reaction. Although it is more expensive because of the use of enzymes, can be more energy efficient and offer higher yields of high quality biodiesel.

Ultrasonic cavitation

It is a technique that has gained interest in the production of biodiesel in recent years. In this process, energy is used ultrasonic high frequency to accelerate and improve the transesterification reaction.

The ultrasonic cavitation generates vapor bubbles in the liquid by the application of sound waves of high intensity. These bubbles collapse rapidly in a phenomenon known as implosion, generating high temperatures and local pressures. This phenomenon helps to break down the oil molecules and accelerate the transesterification reaction, which reduces the reaction times and improves the efficiency of the process.

Some of the benefits associated with the use of ultrasonic cavitation in the production of biodiesel include:

Higher reaction rate: The ultrasonic cavitation accelerates the transesterification reaction, which allows reaction times shorter in comparison with the conventional methods. This can be especially beneficial in terms of production efficiency and time savings.

Improvement of the conversion of oil: The intense agitation and high temperatures and pressures generated during the ultrasonic cavitation help to improve the conversion of oil to methyl esters or ethyl, resulting in a higher yield of biodiesel.

Lower consumption of catalyst: The ultrasonic cavitation can reduce the amount of catalyst required for the reaction of transesterification, resulting in a more efficient and economically viable.

Our plants modular biodiesel use the method of ultrasonic cavitation for the production of biodiesel. They are designed specifically to meet the needs of self-consumption of transportation companies, fleets of vehicles or machines, agricultural.

They are compact and can be easily installed in the place where it is needed to produce biodiesel. Enable enterprises or farmers to generate their own fuel so efficient and convenient, reducing dependence on external sources and saving costs in the long term.

These plants modular tend to be scalable, which means that you can add additional modules to increase the production capacity according to the needs of the client. This provides flexibility to adapt to the growth of the demand for biodiesel in the time.

In addition, by using the method of ultrasonic cavitation, these plants modular can offer additional benefits, such as response times, greater efficiency and better quality of biodiesel produced.