Modules for extraction of vegetable oils

Did you know that there is a comprehensive solution that streamlines and facilitates the mounting of a plant for the extraction of oils?

These modules are designed to provide efficiency and versatility to the process extruding and pressing. Designed for producers of modern, that looks to a great relationship between operations, productivity, simple design and high quality.

With applications ranging from the production of expeller and oil edible as well as for biodiesel production.

This modular plant contemplates from the entrance of the grain in the feeding hopper to the exit of the ejector of the drag tray and the oil to the spillage tray.

The best relationship between efficiency and effectiveness

- Reduces the assembly time and maintenance costs.

- Reduces the space required for the installation of the equipment.

- To facilitate the work of operators and provides for their safety.

- Allows a rapid expansion of the productive capacity by adding new modules.

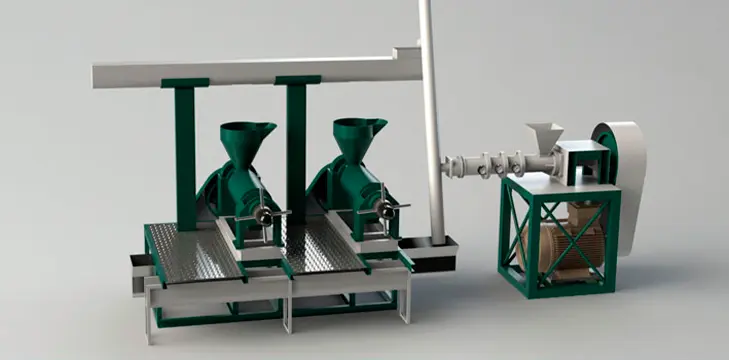

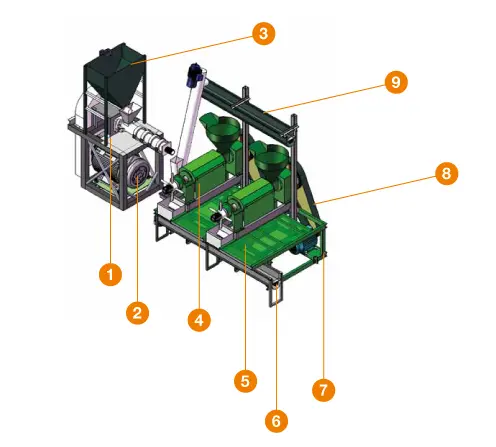

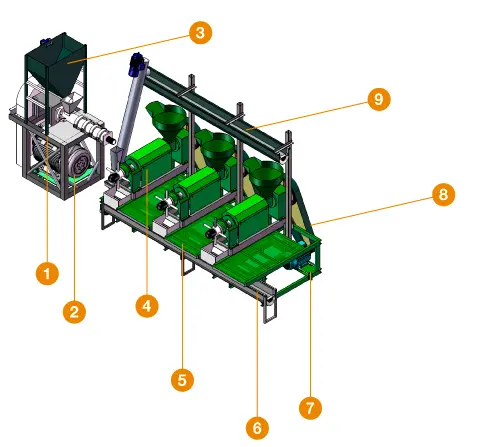

Module Extraction of Oil DWY-100

Production capacity: 1 t/hour.

- Extruder model DS-100

- 2 screw Presses PS-200

- Extruder Mod DS-100 (?)

- Motor Siemens 100 HP

- Hopper of extruder

- Press Oil Mod. PS-200

- Slip-resistant floor removable

- Punt acarreadora of expeller

- Modular structure UPN

- Covers pulleys press

- Punt acarreadora soy extrusada

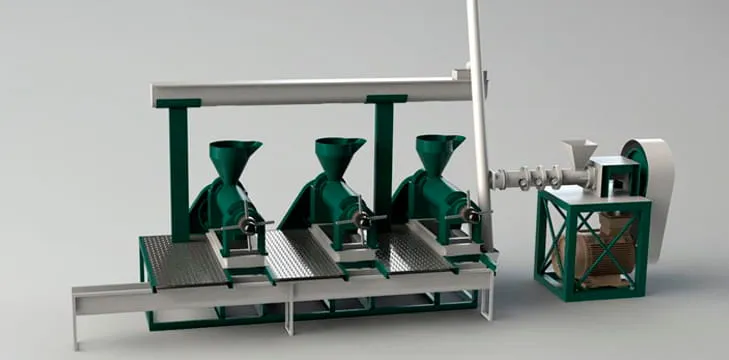

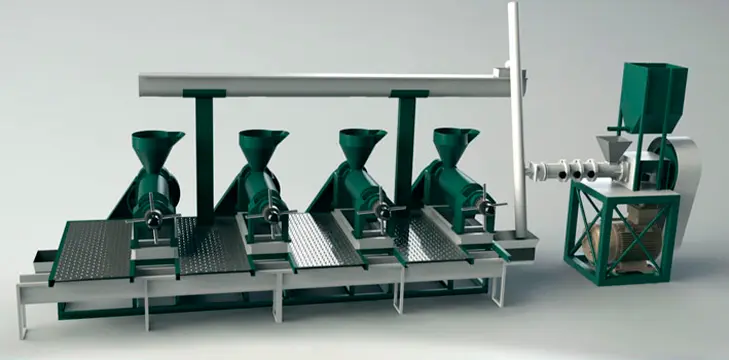

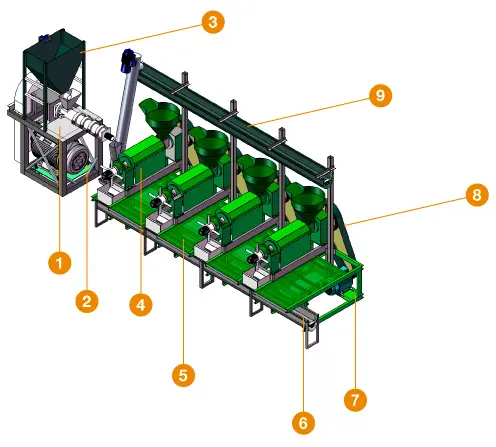

Module Extraction of Oil DWY-150

Production capacity: 1,5 t/hour.

- Extruder model DS-150

- 3 screw Presses PS-200

- Extruder Mod DS-150 (?)

- Motor Siemens 125 HP

- Hopper of extruder

- Press Oil Mod. PS-200

- Slip-resistant floor removable

- Punt acarreadora of expeller

- Modular structure UPN

- Covers pulleys press

- Punt acarreadora soy extrusada

Module Extraction of Oil DWY-200

Production capacity: 2 t/hour

- Extruder model DS-150

- 4 screw Presses PS-200

- Extruder Mod DS-150 (?)

- Motor Siemens 150 HP

- Hopper of extruder

- Press Oil Mod. PS-200

- Slip-resistant floor removable

- Punt acarreadora of expeller

- Modular structure UPN

- Covers pulleys press

- Punt acarreadora soy extrusada

What is the process extrusado and pressed for extraction of oils?

The extruding and pressed system for the extraction of oil is a process used to obtain oil from seeds with high fat content such as soybean, sunflower, rapeseed, canola, etc. Below, I explain what is in each stage:

Extruding: involves the use of a extruder, which is a specialized machine. The seeds are fed into the extruder, where they undergo high temperatures and high pressures controlled. This combination of heat and pressure helps to break down the cells of the seeds and release the oil contained within.

During the extruding, also produces a deactivation of enzyme that reduces the activity of the enzymes present in the seeds, which is beneficial for the quality of the oil end.

Pressing: After the stage of extrusado, the material extruded is directed to the oil press. The press exerts pressure on the material to remove the residual oil present in the solid residues resulting from the extrusado. This pressing process is performed through the use of screws, or plates that compress the material and separate the oil from the solid mass.

The oil that is produced is collected through channels or ducts, and is separated from the solid waste, usually called cakes, that are ejected from the press.

The system extruding and pressing is widely used because of its efficiency in the extraction of oil and that can adapt to different types of seeds with high fat content.

What advantages does this method instead of others?

This method for the extraction of oil offers several advantages in comparison with other methods of extraction:

Higher yield of extraction: The extruding and pressing process allows to obtain a higher yield of oil extraction in comparison with other methods. The combination of the extruding stage, that breaks down the cells of the seeds, and the pressing stage, which applies pressure to extract the residual oil, allows you to make more efficient use of the fat content of the seeds.

Best quality of oil: The extruding and pressing method is smooth and controlled, which helps to preserve the quality of the oil. The use of temperatures and pressures are moderate, minimizes the degradation of the oil and retain its nutritional properties and organoleptic characteristics.

Less use of solvents: unlike other extraction methods, such as extraction with chemical solvents, the extruded and pressed method does not require the use of additional solvents.This makes it a more natural choice, and free of chemical residues.

Increased food security: The extruding and pressing process helps to reduce the enzymatic activity and removes potential pathogens present in the seeds. This contributes to greater food security by minimizing the risks of microbiological processes.

Versatility in the extraction: The extruding and pressing method can be adapted to different types of seeds with a high fat content, such as soybean, sunflower, rapeseed and canola oil. This provides flexibility in the production of oil from different raw materials.

These advantages make the extruding and pressing method an attractive option for oil extraction, especially for those who value the efficiency, quality and safety in the extraction process.

For each 100 kg of seed, the amount of liters of oil that you can get

Soybean ----> 14 litres

Sunflower ---> 32 litres

African palm ----> 36 litres

Sesamo ----> 50 litres

Rapeseed (canola) ----> 37 litres

Moztaza ----> 35 litres

Linen ----> 42 litres

Cotton ----> 13 litres

Mani ----> 42 litres

Castor ricini ----> 36 litres

Jatropha curcas ----> 40-45 liters

Algae cyano ----> 50-60 litres