Desgomadoras oils

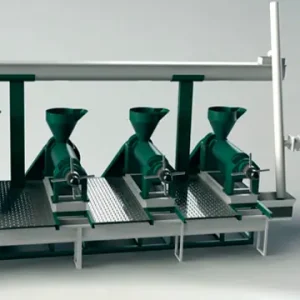

Degumming DG-801

For degumming semi-automatic vegetable oils, virgin raw.

Capacity of 1,000 liters/Bach

- The engine of 10HP

- a carbon steel reactor with a capacity of 1,000 ltrs.

- heat source

- mixed by stirring with a central shaft , propeller and motor reducer

- pumps

- two teams of ULTRASOUND

- two filters of 1500 mm x 600 mm

- automated controls and level of processing cycles

- Platform 2,500 x 4,000 mm of carbon steel , epoxy coated

- electronic board

What is a machine degumming oils?

A machine degumming of oils are used to remove the gums present in the oil. The process of degumming is commonly used in the industry of vegetable oil, especially in the refining of sunflower oil, soybean and rapeseed.

The crude oil extracted from oilseeds often contains impurities, such as phospholipids and proteins, which can form a sticky substance known as rubber. This rubber may cause problems during processing and the storage of the oil, as to hinder the separation of impurities, affect the stability of the oil and produce sediment unwanted.

The oil degumming machine uses a chemical or physical process to remove the gums present in the oil. In the degumming chemical, is added to an aqueous solution of citric acid, phosphoric acid or other acids in the raw oil, resulting in the precipitation of the impurities. Then, it separates the phase gummy oil by centrifugation or filtration.

In the degumming physical, it uses a process of mixing and heating the crude oil with hot water. This helps to hydrate the gums and facilitates its separation from the oil. The mixture is subjected to a decanting or centrifugation to separate the gums from the oil degumming.

The ultimate goal of the oil degumming is to obtain a clean oil, free of gums and other impurities, which improves its quality, flavor, stability and shelf-life. In addition, the degummed oil is more suitable for use in the production of food products and is considered to be more healthy, because the tires can contain unwanted substances, such as heavy metals and pesticide residues.

In summary, a oil degumming machine is used to remove the gums and other impurities present in the crude oil, thereby improving their quality and applicability in various industries.

A machine degumming of oils are used to remove the gums present in the oil. The process of degumming is commonly used in the industry of vegetable oil, especially in the refining of sunflower oil, soybean and rapeseed.

The crude oil extracted from oilseeds often contains impurities, such as phospholipids and proteins, which can form a sticky substance known as rubber. This rubber may cause problems during processing and the storage of the oil, as to hinder the separation of impurities, affect the stability of the oil and produce sediment unwanted.

The oil degumming machine uses a chemical or physical process to remove the gums present in the oil. In the degumming chemical, is added to an aqueous solution of citric acid, phosphoric acid or other acids in the raw oil, resulting in the precipitation of the impurities. Then, it separates the phase gummy oil by centrifugation or filtration.

In the degumming physical, it uses a process of mixing and heating the crude oil with hot water. This helps to hydrate the gums and facilitates its separation from the oil. The mixture is subjected to a decanting or centrifugation to separate the gums from the oil degumming.

The ultimate goal of the oil degumming is to obtain a clean oil, free of gums and other impurities, which improves its quality, flavor, stability and shelf-life. In addition, the degummed oil is more suitable for use in the production of food products and is considered to be more healthy, because the tires can contain unwanted substances, such as heavy metals and pesticide residues.

In summary, a oil degumming machine is used to remove the gums and other impurities present in the crude oil, thereby improving their quality and applicability in various industries.